Product Center

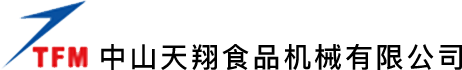

TSM Series Biscuit Sandwich Machine

The production line integrates a full-process process and a full set of equipment covering raw-material blending, forming, baking, sauce coating and cooling. It is equipped with a high-efficiency automation control system that enables precision regulation and consistent product quality. In addition, the line offers high flexibility and scalability, allowing rapid change-over to produce sandwich biscuits of different sizes and flavours in response to market demand.

Product Center

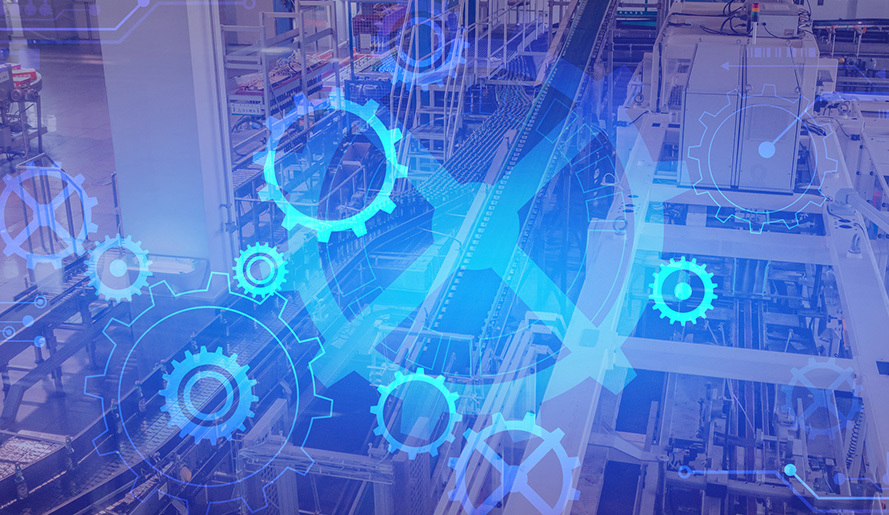

The biscuit sorting production line is an efficient, automated production process that ensures the smooth transition of biscuits from raw materials to finished products. This production line includes multiple stages such as raw material mixing, dough preparation, shaping, baking, cooling, and packaging. Each stage is precisely controlled to ensure the quality and taste of the biscuits. The production line uses advanced machinery to improve production efficiency and accuracy.

Product Center

Automatic Tray-less Biscuit Counting Machine

Biscuits are counted by length-based indexing, stacked in batches and fed into a tray-free wrapper; metering units with configurable lane numbers are supplied to match any required output.

Product Center

Product Center

Product Center

TSM Series Biscuit Sandwich Machine

The production line integrates a full-process process and a full set of equipment covering raw-material blending, forming, baking, sauce coating and cooling. It is equipped with a high-efficiency automation control system that enables precision regulation and consistent product quality. In addition, the line offers high flexibility and scalability, allowing rapid change-over to produce sandwich biscuits of different sizes and flavours in response to market demand.

The biscuit sorting production line is an efficient, automated production process that ensures the smooth transition of biscuits from raw materials to finished products. This production line includes multiple stages such as raw material mixing, dough preparation, shaping, baking, cooling, and packaging. Each stage is precisely controlled to ensure the quality and taste of the biscuits. The production line uses advanced machinery to improve production efficiency and accuracy.

Automatic Tray-less Biscuit Counting Machine

Biscuits are counted by length-based indexing, stacked in batches and fed into a tray-free wrapper; metering units with configurable lane numbers are supplied to match any required output.

Latest Product Display

About Us

Zhongshan Tianxiang Food Machinery Co., Ltd.

Professional Design, Production, and Sales of Biscuit Post-processing Equipment

TFM Company (TIANXIANG FOOD MACHINERY), established in 2007, has now founded Zhuhai Tianxiang Food Machinery Manufacturing Co., Ltd., Zhongshan Tianxiang Food Machinery Co., Ltd., and Australia Tianxiang Development Co., Ltd.

TFM is a good partner for biscuit factories, specializing in designing, producing, and selling biscuit post-processing equipment: biscuit regrouping or diversion conveyors, combined or separated conveyors, vibrating conveyors, biscuit fillings with various fillings (jam, maltose, nougat, pineapple jam, cream, etc.), and various forms of packaging quantitative biscuit feeders. Customized according to the customer's product types, output, packaging methods, and workshop space size, the most ideal design plan is formulated to achieve semi-automatic and fully automated assembly line operations, improve product quality, reduce defective products, reduce secondary pollution, lower labor intensity, and increase production efficiency.

Company Established

Providing Solutions

Countries and Regions Served

Why Choose Us?

Customized Professional Solutions

Diverse Company Layout

Adhering to Innovation Concepts

International Certification and Bestselling

Customized Professional Solutions

Tailored to the customer's various conditions to achieve automated assembly line operations, effectively improving quality and efficiency, reducing defective products and pollution.

View More

Diverse Company Layout

Since its establishment in 2007, multiple subsidiaries have been founded, distributed in many locations and overseas, expanding business coverage and continuously strengthening capabilities.

View More

Adhering to Innovation Concepts

Adhering to a unique philosophy, actively researching and innovating, winning four national patents, creating numerous successful solutions for customers with wisdom and passion.

View More

International Certification and Bestselling

Products have passed CE certification, connecting with the world, selling well in dozens of countries across continents, and becoming a designated supplier for American companies, cooperating with many large enterprises.

View MoreNews & Blog

Lifecycle of the Automatic Duplicate Checking Scale

2025-07-21

There is no one-size-fits-all checkweighing solution. Each production line is different, and the specific conditions of your equipment determine the specifications required for the automatic checkweigher. Before making a purchase decision, you should carefully evaluate the various features and specifications of the automatic checkweigher to ensure that the model is truly suitable for your production line. Before making such an investment decision, factors such as product weight and characteristics, packaging type, and the position of the automatic checkweigher on the production line should be considered.

View DetailsUrbanization construction provides new opportunities for the packaging industry

With the rapid and healthy development of China's national economy, China's packaging industry has become a highly promising sector with broad market potential. The national urbanization rate is expected to increase from the current 39.1% to 60% by 2020. The annual average growth of urban residents nationwide will be 1%, increasing from the current 502 million to about 900 million by 2020;

2025-07-21

Development Trend of Automation Level in the Process Flow

The level of automation in the process flow is increasing. Currently, automation technology accounts for more than 50% in packaging production lines, extensively using computer design and mechatronic control to improve productivity, equipment flexibility, and adaptability, and adding robotic arms to perform complex packaging actions.

2025-07-21

In 2014, the sales volume of plastic flexible packaging in the global food industry increased by 3%, reaching 1.9 trillion units, and it is expected that the global sales volume will rise to 2 trillion units by 2016. Market research company Euromonitor International stated that in the food industry, stand-up pouches are undoubtedly one of the fastest-growing types of plastic packaging. Stand-up pouches remain a packaging form favored by many brand owners. According to Euromonitor International's forecast, the annual sales volume of stand-up pouches will increase by 6% during the period from 2014 to 2019. Among the stand-up pouch packaging released in 2014, notable examples include the cereal products launched by Kellogg's, the world's largest cereal breakfast manufacturer, in France.

2025-01-10

6 Golden Rules to Improve Efficiency

Before purchasing a weighing system, you should first carefully consider the weighing operation environment and the characteristics of your product. Factors such as humidity, temperature changes, dryness, excessive vibration, and airborne dust can all negatively affect weighing accuracy. If the operating conditions are poor, with high humidity and dust content in the air, moisture and dust can enter and damage the mechanical components of the conveyor belt and weighing sensors, thereby shortening the machine's service life.

2025-06-27

How to Enhance the Strength of China's Packaging Machinery Industry

Currently, most of the advanced data technology packaging machinery in our country is still in the imitation stage. There are very few domestic packaging machinery manufacturers with specialized research and development capabilities, and the ability for independent development is still very limited. To meet the rapid development needs of the food and pharmaceutical industries and actively participate in international competition, our packaging machinery industry must break the "small and scattered" industry pattern and continuously advance in the directions of "high, precise, and cutting-edge."

2025-01-10